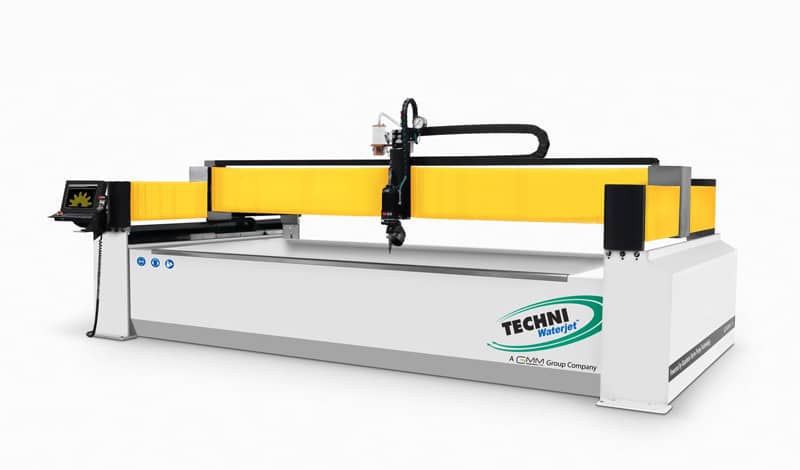

Intec-G2® Water Jet Cutting Machine

The Intec-G2® waterjet machine will bring tremendous benefits and expanded capabilities to your operation. Below we have listed some of the many possibilities that are available to you through the use of our waterjet machines.

Why should you use an Intec-G2® series waterjet machine?

Easy operation means that no special skills are required to produce precise parts from any material.

Outstanding edge quality means more time saved in post-processing.

Lights out cutting means that the machine continues to earn money while you do what you want or need to do.

Versatile cutting enables cutting of different material types on the same bed without having to change the tool.

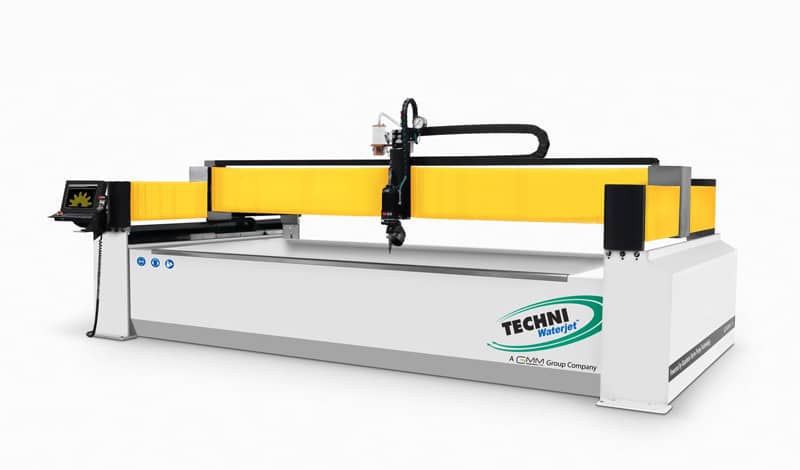

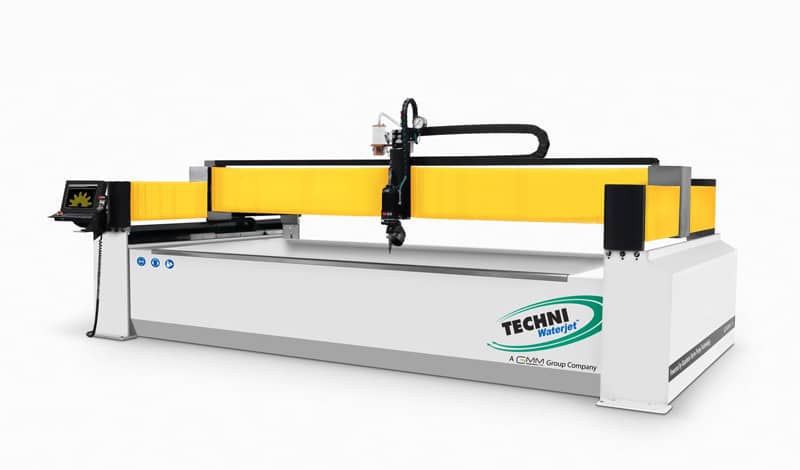

MACHINE OVERVIEW

Intec-G2® Water Jet Machine

Introduction

Intec-G2® Series

All our Intec-G2® series waterjet machines are equipped with the latest developments

and features to ensure maximum accuracy and cutting performance.

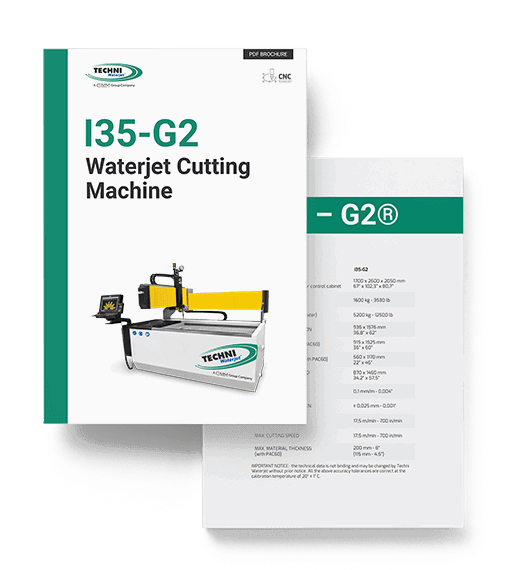

I35 – G2

936 x 1576 mm

Waterjet cutting machine

| Machine Size | 1700L x 2600W x 2050H mm |

| Cutting Table Size | 936 x 1576 mm |

| Machine Type | Cantilever |

| Accuracy of Motion | ±0,1mm – 0,004″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

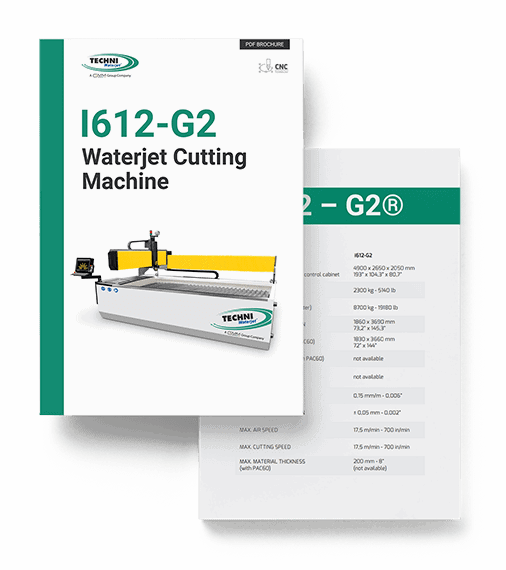

I612 – G2

1860 x 3690 mm

Waterjet cutting machine

| Machine Size | 4900L x 2650W x 2050H mm |

| Cutting Table Size | 1860 x 3690 mm |

| Machine Type | Cantilever |

| Accuracy of Motion | ±0,15mm – 0,006″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

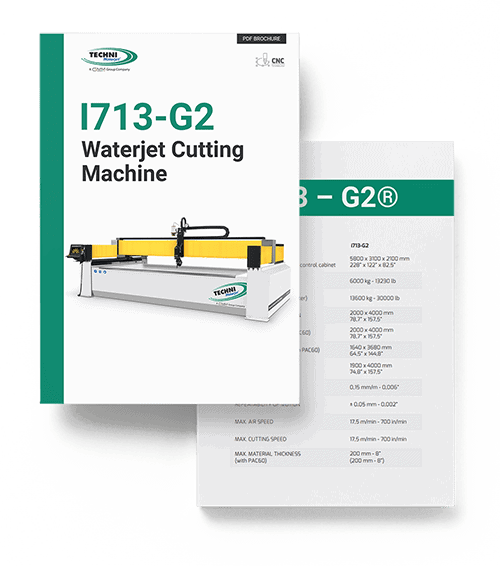

I713 – G2

2000 x 4000 mm

Waterjet cutting machine

| Machine Size | 5800L x 3100W x 2100H mm |

| Cutting Table Size | 2000 x 4000 mm |

| Machine Type | Portal |

| Accuracy of Motion | ±0,15mm – 0,006″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

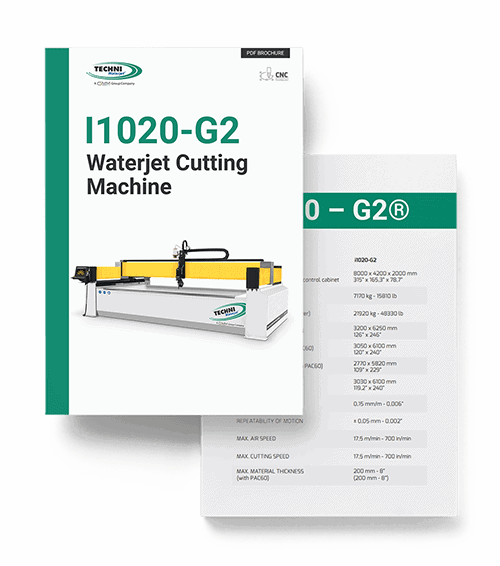

I1020 – G2

3200 x 6250 mm

Waterjet cutting machine

| Machine Size | 8000L x 4200W x 2000H mm |

| Cutting Table Size | 3200 x 6250 mm |

| Machine Type | Portal |

| Accuracy of Motion | ±0,15mm – 0,006″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

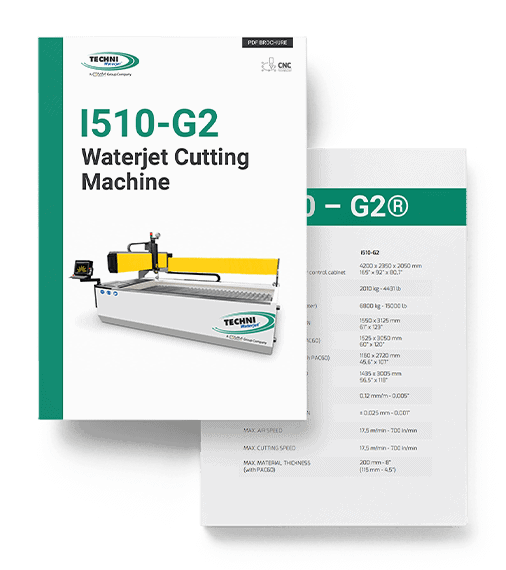

I510 – G2

1550 x 3125 mm

Waterjet cutting machine

| Machine Size | 4200L x 2350W x 2050H mm |

| Cutting Table Size | 1550 x 3125 mm |

| Machine Type | Cantilever |

| Accuracy of Motion | ±0,12mm – 0,005″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

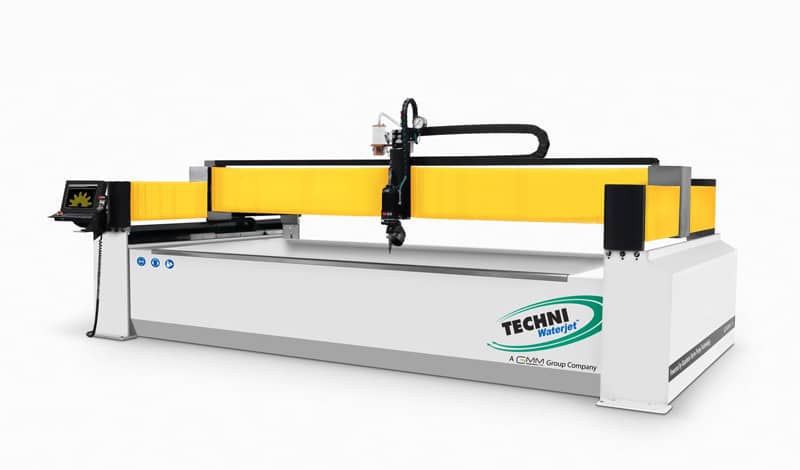

I613 – G2

1930 x 3870 mm

Waterjet cutting machine

| Machine Size | 5200L x 2700W x 2300H mm |

| Cutting Table Size | 1930 x 3870 mm |

| Machine Type | Monoblock |

| Accuracy of Motion | ±0,12mm – 0,005″ |

| Max Material Thickness | 130mm – 5″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

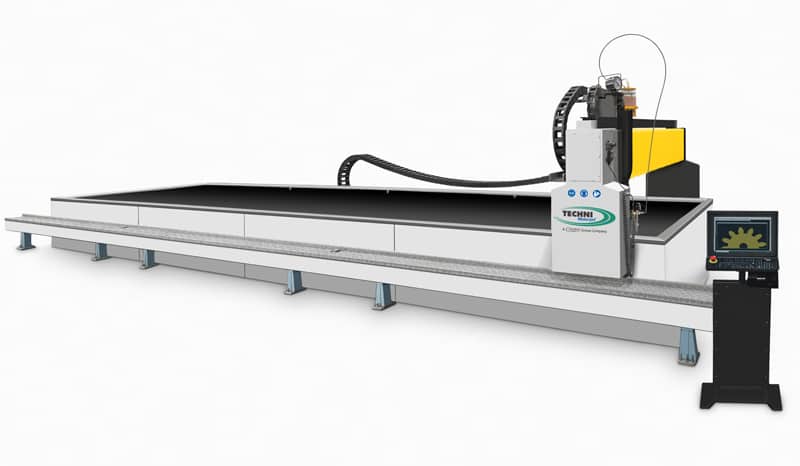

I815 – G2

2380 x 4780 mm

Waterjet cutting machine

| Machine Size | 6580L x 3500W x 2100H mm |

| Cutting Table Size | 2380 x 4780 mm |

| Machine Type | Portal |

| Accuracy of Motion | ±0,15mm – 0,006″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

I1033XL – G2

10150 x 3270 mm

Waterjet cutting machine

| Machine Size | 12800 x 5400 x 2200 mm |

| Cutting Table Size | 10150 x 3270 mm 399.6” x 128.7” |

| Machine Type | Portal |

| Accuracy of Motion | ±0,1mm – 0,004″ |

| Max Material Thickness | 200mm – 8″ |

| Materials that can be Cut | Listed here |

| Price | Enquire for Price |

Standard Features

Intec-G2® Series

REMOTE

The MPG allows to manually wind forward or backward through a cutting path. This enables the operator to find the exact point along a cutting path from which to re-start cutting after a stoppage or to accurately locate a pre-cut part.

BREAK AWAY HEAD

When the cutting head inadvertently crashes into a clamp or fixture or hits the edge of a work piece or an upturned part, the Break Away Head will detect the crash and automatically stop the machine.

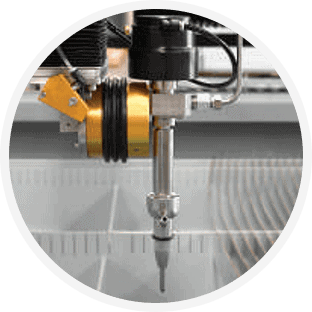

SERVO Z AXIS

Programmable Z axis with auto height position recall, laser terrain mapping and edge location optics.

WATER RAISE & LOWER

Automatic water Raise/Lower at the push of a button for submerged cutting: our tanks include airtight welds of an air chamber which uses regular shop air pressure. No moving parts are required, an on/off solenoid valve allows water level adjustment within a few seconds.

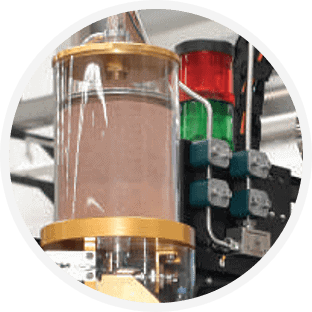

TECH SENSE

Tech Sense monitoring system provides the ability to run a night shift without the need for an attending operator. Should the cutting be disrupted e.g. blocked nozzle, the machine will pause the program and send a text message to your cell phone (SMS Notification option must be fitted.)

For perfect manufacturing

Water treatment and garnet supply & removal

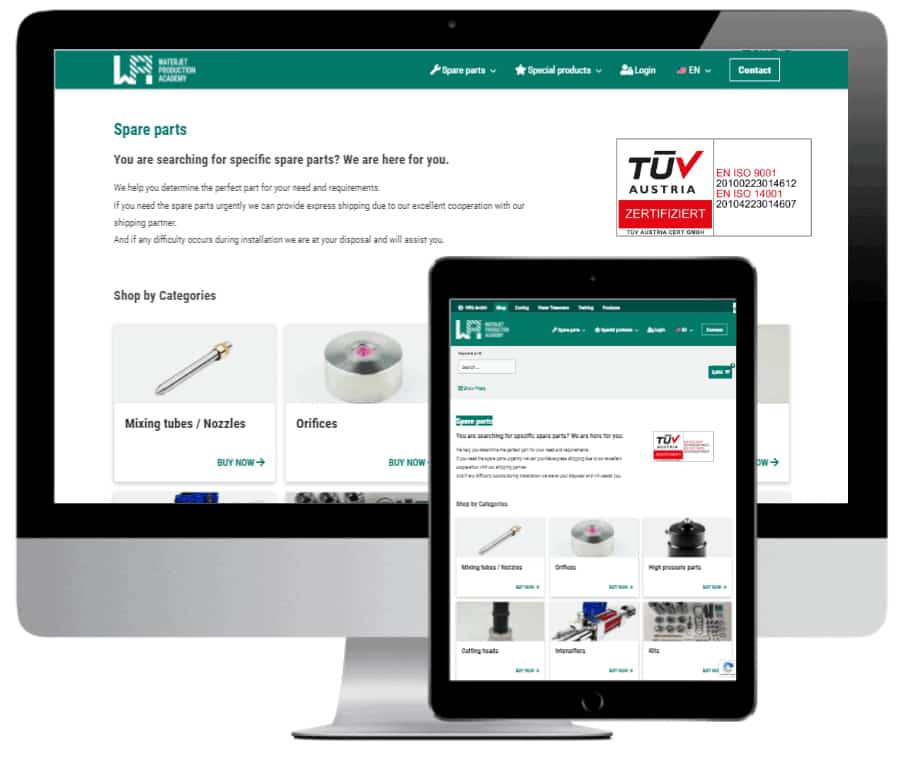

Are you looking for specific spare parts? We are here for you.

Find spare parts for your water jet machine!

We can help you determine the perfect part for your needs and requirements.

If you need the spare parts urgently, we can offer express shipping due to our good cooperation with our shipping partner. And if there are any difficulties during the installation, we are here to help you.