Light Series

The first step into the

Quantum World

Cut soft materials such as foam, food and glass without pressure fluctuations, which is crucial for the quality of these materials. Thanks to the incredibly small footprint, the machine fits easily into any workshop.

VP 15/52, 20/60 (KW/PSI)

Applications with water only

Food cutting

Small footprint

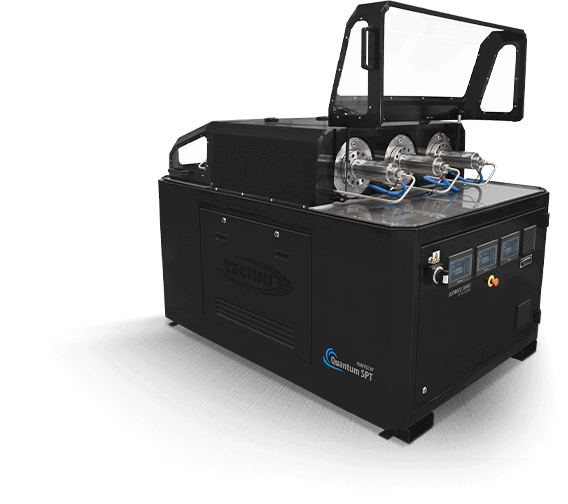

Power Series

Universal Quantum Solution

Cut any type of material with ease and smooth edges. Advanced diagnostics enable predictive maintenance; built-in router supports remote maintenance from anywhere in the world.

ESP 37/66 40/60 (KW/PSI)

High flow oil filter

Larger plunger

Booster-Pump

Built-in router for remote maintenance

Advanced diagnostics

Ultimate Series

The ultimate Quantum experience

Cut everything at maximum speed for demanding production with peace of mind. Despite its incredible capabilities, this waterjet pump withstands the workload without compromising its reliability and consumable life.

ESP UL 45/4100, ESP UP 40/6000 (KW/BAR)

Heavy duty frame

Integrated LP water filters

External cartridge check valves

Durable, quickly replaceable seals

Built-in router for remote maintenance

Advanced diagnostics

Key features of the Quantum NXT™ waterjet pump series

Predictive diagnostics

High-tech sensors, on both the oil and water circuits, enable communication with the pump. This information, combined with servo-drive technology, is fed into a computer that has incorporated more than 30 years of waterjet experience to develop algorithms that accurately predict when maintenance is required, minimizing unplanned downtime. Thanks to the integrated router, the pump is visible online to a technician, who can perform live troubleshooting.

- Diagnose potential maintenance problems

- Give advice on how to carry out the maintenance

Designed for efficiency

The patented direct drive servo technology is up to 60% more efficient than a typical hydraulic pressure intensifier. Superior pressure control also maintains constant pressure during cutting, resulting in smoother edges and less spent garnet for each cut.

- Reduced carbon footprint due to less energy needed

- Can direct the energy generated to the areas that need it

Reduced maintenance

Compared to direct-drive pumps, the Quantum NXT requires less maintenance. This is due to the speed of the plunger when moving back and forth. Its superior design with visual diagnostics allows easy, quick and ergonomic access to the pump when maintenance is required. In addition, typical hydraulic intensifiers have pressure spikes of 10% or more when the cutting head opens and closes, which significantly reduces the life of the HP pipes and fittings.

- Minimised machine downtime

- Saves maintenance and servicing costs

Environmentally friendly

The ESP not only significantly reduces power consumption, but also uses far less cooling water than conventional hydraulic intensifiers. Combined with the fact that our pumps have minimal oil consumption compared to competitive products, this makes it the best pump available for the environment.

- Reduced power consumption

- Reduzierter Wasserbedarf

Ultimate Series Design

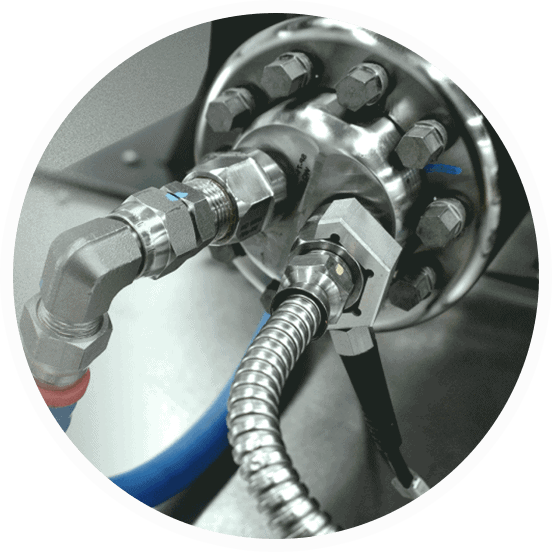

Check valve and seal

Cut everything at maximum speed for demanding production with peace of mind. Despite its incredible capabilities, this waterjet pump withstands the workload without compromising its reliability and consumable life.

Quick change seal

External cartridge check valves

Ultimate Production

Waterjet Pumps

Dual

MAXIMUM OUTPUT VOLUME

6.0 L/MIN – 6000 BAR MODEL

8.4 L/MIN – 4500 BAR MODEL

Triple

MAXIMUM OUTPUT VOLUME

9.0 L/MIN – 6000 BAR MODEL

12.6 L/MIN – 4500 BAR MODEL

Quad

MAXIMUM OUTPUT VOLUME

12.0 L/MIN – 6000 BAR MODEL

16.8 L/MIN – 4500 BAR MODEL

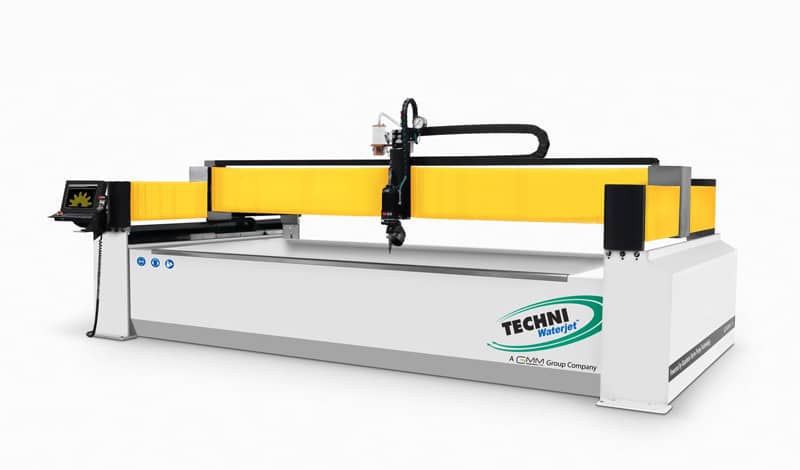

Intec-G2® Water Jet Cutting Machine

The Intec-G2® waterjet machine will bring tremendous benefits and expanded capabilities to your operation. Below we have listed some of the many possibilities that are available to you through the use of our waterjet machines.

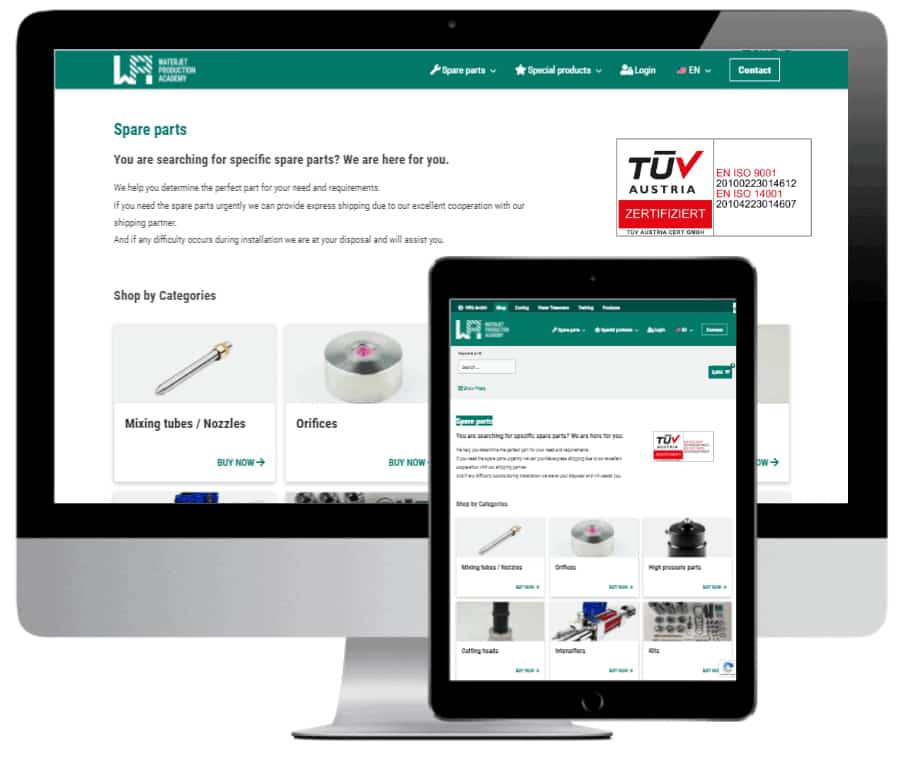

Are you looking for specific spare parts? We are here for you.

Find spare parts for your water jet machine!

We can help you determine the perfect part for your needs and requirements.

If you need the spare parts urgently, we can offer express shipping due to our good cooperation with our shipping partner. And if there are any difficulties during the installation, we are here to help you.