Set the bar higher.

Equip your waterjet machine with attachments that enhance your cutting capabilities.

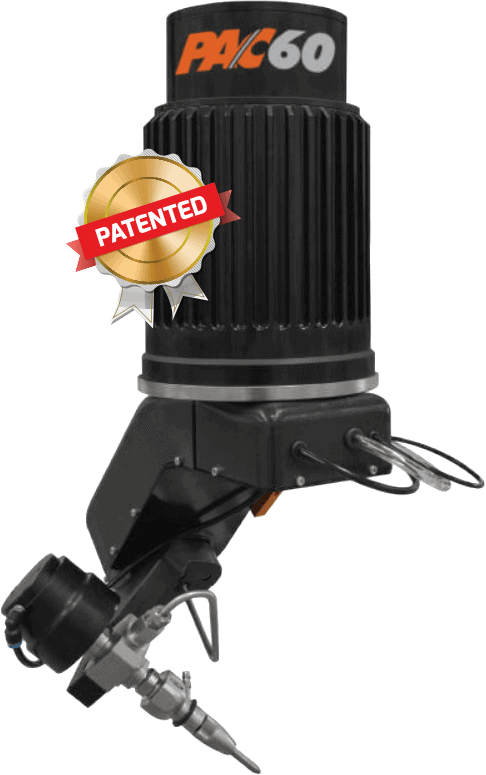

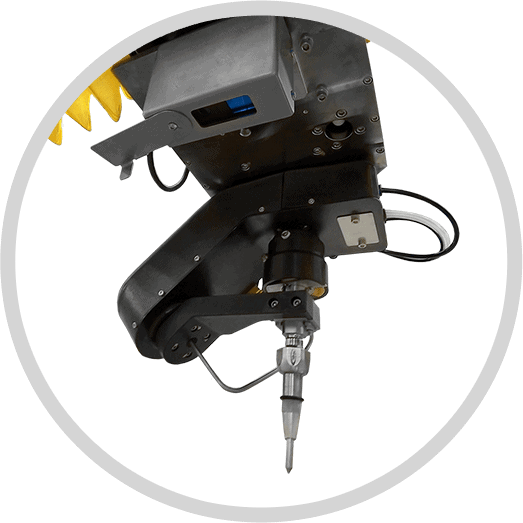

PAC 60™ 5-Axis Head

Produce Parts with a True Angel Up to +/- 60 Degrees

The PAC 60™ is capable of producing parts with a true angle up to +/- 60 degrees, with continuous rotation. That means, regardless of the geometry of the part to be cut, the PAC 60™ will produce accurate parts without having to reposition the cutting head, saving time and producing higher quality parts.

Twice the Power

Twice the Speed

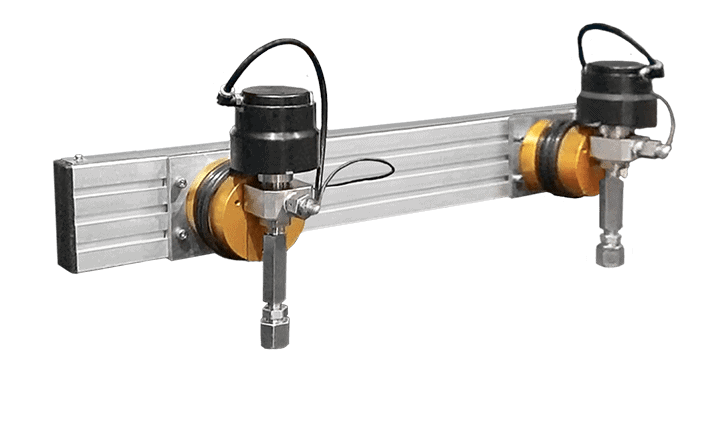

The option of multiple cutting heads gives the Techni Waterjet™ Cutting Machine the power and speed to provide the highest level of productivity, in the most demanding production environments.

Option 1 is mounted on an aluminum spreader bar, the cutting heads can be quickly and easily positioned whilst still featuring the unique breakaway head configuration. This feature allows the machine to automatically shut down one of the cutting heads if either one of them comes into contact with a foreign object such a fixing clamp.

Option 2 is Independently mounted cutting heads, which allows for an accurate stand-off to be set and maintained on each cutting head.

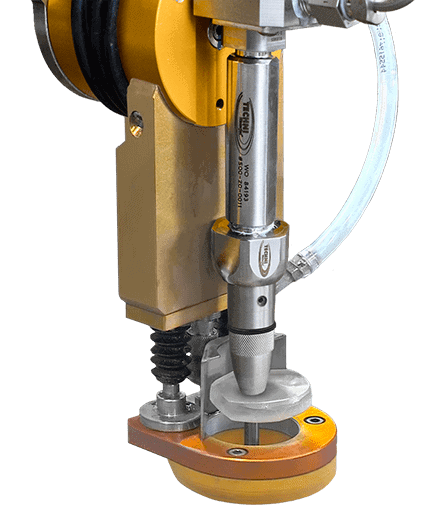

Maintain Optimal Height

Sheet materials are often subject to warping. The Skip and Float feature will ensure the cutting head is maintained at the optimal stand-off height above the material being cut (via the float mechanism). Without this feature, warped material can cause the cutting head to hit the material and break the focusing tube, or to partially block and not cut through the material.

The skip function automatically raises the cutting head well above the material when traversing between cuts. This ensures that the cutting head cannot catch on a cut part which may have tilted and risen above the materials. This will ensure that the focusing tube isn’t broken and the workpiece isn’t moved or damaged.

EXPERIENCE SUPER ACCURATE CUTS WITH

Terrain Mapping

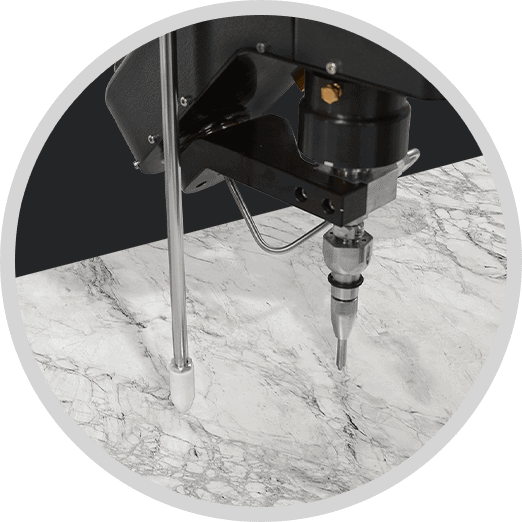

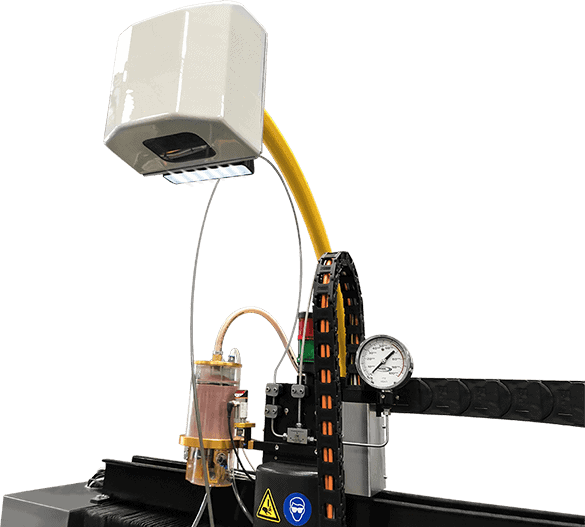

Touch - Probe

The Touch - Probe Height Detection option performs reliable and accurate terrain mapping on the material surface, allowing the cutting head to automatically adjust its distance before piercing and during the cutting process.

By touching the surface of the plate, differences in thickness can be detected and the Z-height compensated. This is especially important to avoid unexpected results when bevelling.

Laser

The optional laser sensor performs precise terrain mapping on the surface of the material to be cut. This information is then used to maintain a precise distance between the nozzle and the workpiece, resulting in more accurate parts than any other cutting head on the market. Other cutting heads only set their distance at the piercing point and then assume that the workpiece is completely flat along the cutting path, which is almost never the case.

As the flatness of the material and the distance vary, the geometry of the part to be cut also changes. Constant, accurate spacing is critical in angle cutting, and the greater the angle, the more critical it becomes.

PANEEL-MATCHING

It has never been so easy

Until now

Tech – Vision

Tech - Vision is a highly sophisticated camera mounted above the machine bed that captures a bird's eye view of the material being cut.

This allows the operator to effectively perform book edges, waterfall edges and match patterns in materials such as stone to ensure the final product is exactly what the customer wants.

In addition, the Tech Vision camera's eye makes it much easier for the operator to ensure that the tabletop is positioned correctly before starting to cut. This avoids waste that would result from inaccurate plate alignment.

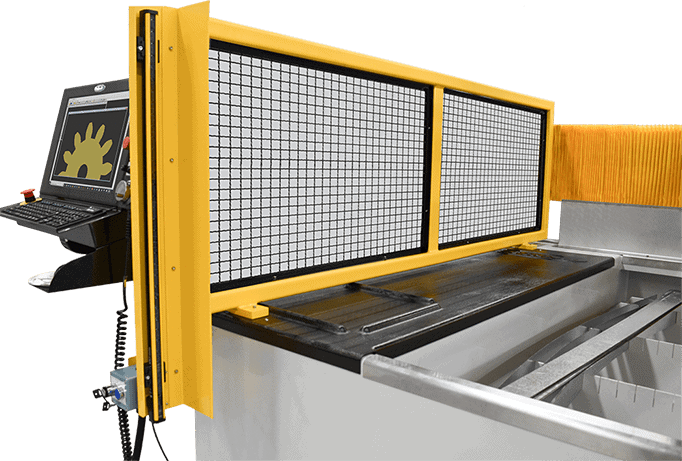

Protect your employees

With water jet safety light curtains

Many high-pressure waterjet customers require an extra measure of safety by protecting the front loading/unloading area of the waterjet unit with a light curtain.

The light curtain allows the operator access only when the cutting cycle is completed and the high-pressure water jet is switched off.

If the operator breaks the light curtain during cutting, then the circuit is interrupted, the system is automatically switched off and the high-pressure water is drained.

The side fencing prevents the operator from entering the machine from the side, access is only possible from the front. The safety light curtain consists of a transmitter and a receiver unit attached to the side safety fence.

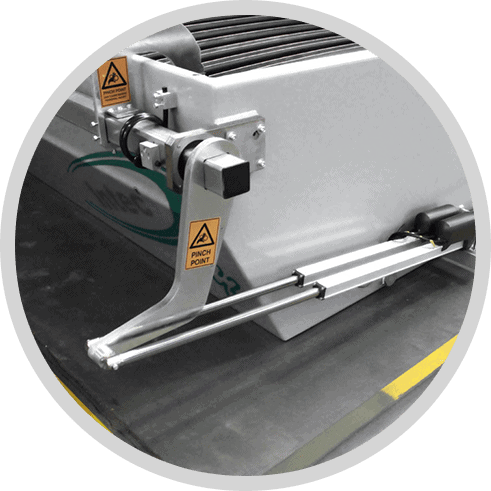

EZY- Load lifter

Easily position fragile material such as glass & stone.

The Ezy Load Lifter's electrically operated tilt arms allow easy vertical loading and unloading of fragile materials such as glass and stone to lighten the load.

Most of the time, materials such as the ones mentioned are subjected to a lot of stress when they are loaded and unloaded onto the machine bed, which is why hairline cracks, cracks and complete fractures can occur in the material when it is lifted in the horizontal plane.